Dating back to at least medieval times, Damascus steel has been used for centuries to make the highest quality tools. This ancient art form continues to be relevant today through its uses.

Such as custom knife making, crafting exquisite chef knives Damascus, and even creating unique weapons like beard Viking axes. Learn all about this elegant metal here and discover its history, properties, and modern applications.

What is Damascus Steel?

It’s a type of steel alloy with a distinctive pattern created by alternating layers of iron and steel. It is renowned for its strength and durability, which has given it enduring popularity throughout the centuries.

Combining elements from traditional smelting techniques, such as folding and hammering, and modern technology, this material can be crafted into knives, tools, or weapons of superior quality.

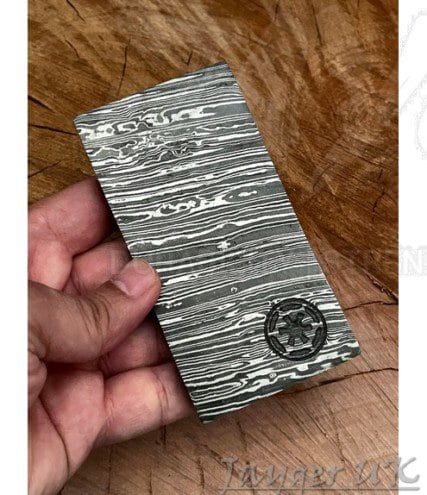

The Beauty of the Layered Pattern

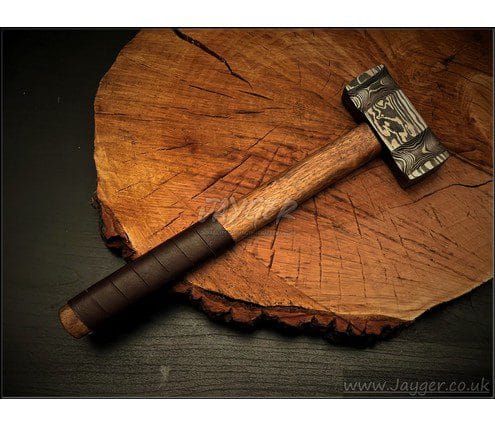

The layered pattern characteristic of Damascus steel is one of its most alluring traits. This pattern is formed as liquid metal is folded and pounded several times, creating an interlaying of two different metals that provides a stunning effect. The distinctive patterns make each piece of this steel unique and a sight to behold.

The History and Making of Damascus Steel

The forged steel alloy known for its strength and beauty originated in the Middle East during the 13th century in the history of Damascus knives.

This steel was famously used to make swords, daggers, and other weapons. That was strong enough to keep their edge even after piercing through enemy armor.

Damascus steel was crafted with extreme attention and tempering techniques to form a durable surface. While also incorporating softer iron into its center for flexibility.

These methods can still be used today by modern smiths and artisans to produce custom knife making products of the highest quality.

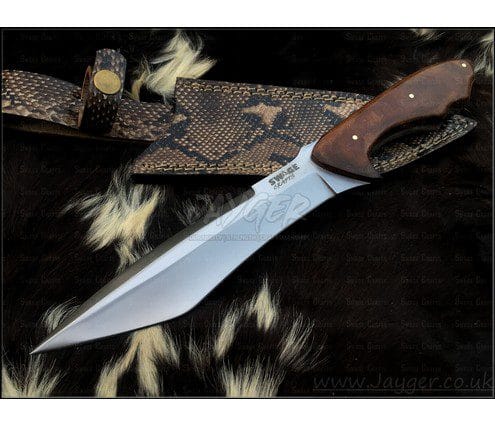

Benefits of Damascus Steel for Knives

Damascus Steel is commonly used for making custom knives. Its unparalleled strength and unique design allow it to be molded into various shapes with remarkable accuracy. Its durability also makes it highly resistant to wear or breakage.

Which allows the knife to maintain its edge for much longer than traditional steel.

The uncommon patterning of this steel also gives custom knives a striking appearance that can only be achieved by combining several metals in precise ways.

The Role of the Blacksmith in Crafting Damascus Steel Knives

The blacksmith is the backbone of Damascus steel craftsmanship and is pivotal in creating a strong, sharp, and stunningly beautiful knife. Skilled artisans take great care over each process step to ensure that the blade looks great and can stand up to years of hard use.

This includes shaping the metal into a formable billet, etching it with chemicals to bring out distinctive patterns, heat-treating it to create strength and durability, and carefully grinding it for sharpness.

Types of Damascus Steel

This steel comes in various varieties, depending on the type of metal used in its construction.

These include modern stainless steel alloys, such as VG-10 and 13C26, and ancient metals, like iron meteorite and high-carbon steels. The variety you choose will depend on your particular needs, from custom knives to chef knives for professional kitchens.

The combination of artistry and science that goes into creating different types of Damascus steel ensures that no two blades are the same.

What Makes it Unique?

Damascus is known for its unique characteristics, including strength and durability. It’s created using a layered forging technique and has a distinctive “Damascene” pattern, which exudes an almost ethereal beauty when the light catches it.

The pattern is made up of alternating layers of different types of steel, such as 1095 carbon steel, 15N20 nickel steel, and 1018 low-carbon steel. When these layers are forged together by hammering them at high temperatures, the harder steels burnish over time to create the iconic Damascene patterns.

The Traditional Techniques Used in Making Damascus Steel Knives

The artistry of Damascus steel begins with traditional techniques that are centuries old. These include hammering and annealing, which involves heating the metal to a specific temperature before cooling it to ensure optimum hardness.

The materials used in creating this elegant steel are also integral to its strength and durability.

Old versions often combined high-carbon steels like Wootz steel with softer metals such as brass or nickel forges welded together.

Modern methods may involve additional steps, like vacuum heat treating or cryogenic tempering, for added toughness and toughness retention.

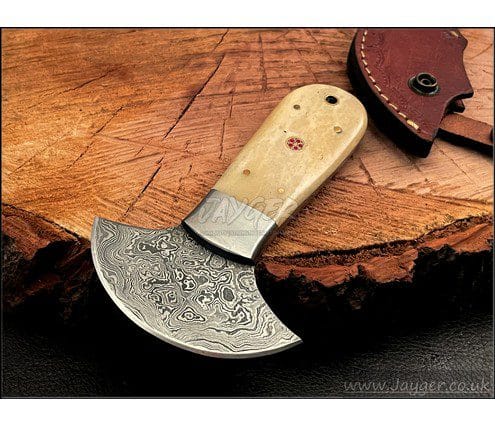

Forging Techniques

The forging techniques used in crafting this steel are intricate and complicated. The process begins with the billets being cut into specific repeating patterns. Such as a ladder pattern, and then welded together in layers.

When this has been achieved, the blacksmith hammers the material over an anvil, creating ridges and furrows that give it its distinctive pattern and texture. This hammering process is known as pattern-welding or Damascening. Additional heat treatment steps ensure maximum strength and durability in the final product.

Variations in Design and Pattern of Damascus Steel Knives

Along with its strength and resilience, one of the most distinguishing qualities of Damascus is its intricate patterning. This design feature is created as part of the heat-treating process and depends on several factors, including the temperature applied and the type of steel combined.

Different knife makers like Jayger use various techniques to create distinctive patterns that make each knife genuinely unique. Typical patterns for Damascus steel include wavy lines, geometric shapes, and swirls.

Care and Maintenance

Damascus blades are incredibly resilient and long-lasting; however. They require proper storage with care and maintenance to ensure they remain in optimal condition. For starters, it’s essential to use high-quality blade oil or wax on them after every use.

This will prevent oxidation and ensure the blade is rust-free. Allowing you to get the most out of your custom knives. It’s also essential to give them the occasional deep cleaning by soaking them in mineral oil or warm soap suds before wiping them with a soft cloth.

Also, store the knife in a dark and dry place when not in use, as this will increase its lifespan significantly.

Benefits of Investing in a Damascus Steel Knife

Investing in a Damascus steel knife is an excellent way to ensure you have a knife that is reliable, durable, and resistant to rusting. Unlike other blade steels, Damascus steel knives don’t require much maintenance beyond regular cleaning.

Each blade has its unique pattern and appearance, making them highly sought after by chefs worldwide. When cared for properly, these sharp blades can last a lifetime and provide plenty of use allowing you to cut through anything from thick cuts of meat to delicate vegetables with the most excellent ease!

Role of Heat Treatment in Enhancing the Artistry of Damascus Steel Knives

Heat treatment plays a crucial role in enhancing and preserving the artistry of Damascus steel knives. Consisting of many layers of different alloys, this type of steel is specially heat-treated throughout the forging process to create its signature patterning.

The heat melts and fuses small pieces of stainless and carbon steel, creating an alloy with superior strength and resilience. The result is a beautiful, robust weapon or tool that can stand up to the job.

The Science Behind Heat Treating Damascus Steel.

The precise process by which this steel gets its unique qualities is called heat treatment.

During this process, the material is heated to very high temperatures and then quickly cooled.

Doing this releases martensite a crystalline form of iron. That gives Damascus steel superior hardness, strength, and durability compared to ordinary steel.

Heat-treating also allows the maker to create various designs and patterns in the metal. Depending on the processes used, with each pattern imbuing each blade with artistic characteristics and enhanced performance.

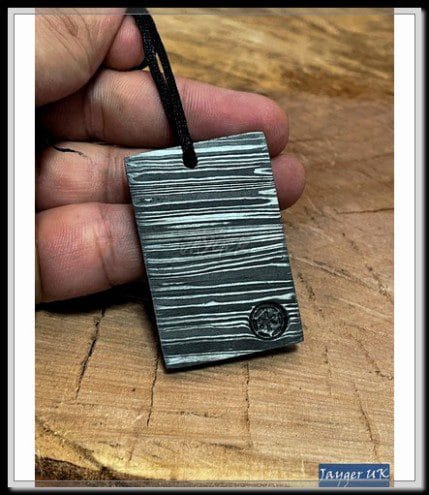

Uses of Damascus Steel in Modern Times

While Damascus Steel is often used in making knives and other tools. It has also been used in various modern applications.

For example, it is used to make armor plating, decorative art pieces, and even pendants.

Due to its unique ability to resist damage. Many jewelers and watchmakers have begun to utilize it to produce fine jewelry and watches.

Its strength and unique patterning make it covered by those who value aesthetics and practicality.

Advanced Annealing Processes for Crafting Durable Blades

One of the most critical steps during the heat-treatment process for creating a Damascus blade is annealing.

This process involves soaking metal at a higher temperature than other steel types, allowing it to relax and releasing impurities from the material.

As a result, this produces one of the most robust and durable types of steel, allowing it to be formed into custom knives that are strong enough to slice through almost anything while maintaining their edge and sharpness without being brittle or prone to damage.