What Does Every Knife Maker Need?

Making stunning knives and tools requires the perfect balance between quality materials and craftsmanship.

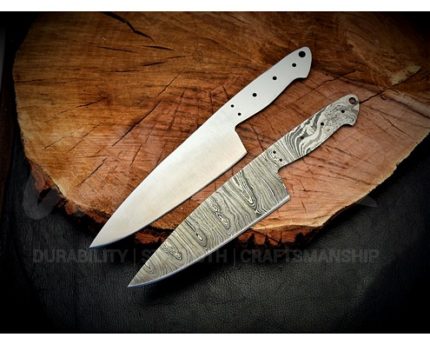

Every knife maker needs quality materials to craft a successful project: Damascus steel billet,1095 steel, and other top-of-the-line knife making supplies UK for crafting beautiful blades.

Knife billets, Corby bolts, and other essential items are critical in helping the knife-maker create their vision. Before starting your next knife making Kit UK project, ensure you have all the necessary supplies—from your preferred handle material and billet to professional sharpening stones or hones.

What Equipment Do You Need to Bladesmith?

If you already have a forge, anvil and hammer, you’re one step ahead. Make sure to stock up on supplies like safety glasses, leather gloves, and aprons.

You’ll also need to invest in a power hammer or press if you want the full functionality that comes with smithing blades professionally. Of course, you will get far with high-quality metals such as 1095 steel and Damascus steel billets!

You’ll also need grinding and polishing tools like files, stones, sanders and polishers. High-quality bladesmithing materials like basaltic stone, a high-definition wheel grinder,

How Long Does it Take to Make a Knife?

The time required to make a knife varies for each project, depending on the complexity of the design, the type of steel being used, and any other desired embellishments. From start to finish, an essential knife with no details will take anywhere between six and eight hours.

A more advanced knife can take up to twice that amount of time or more. If a particular blade is decorated with engravings or another elaborate detail, that can add several hours to your total work time.

Highly intricate and ornate knives may require additional time for design and detailing, which can increase the project length from three to five hours.

What are the 7 Parts of Knives

Every knife maker needs quality materials to craft a beautiful and durable knife. At the very least, you’ll need seven parts for each best handmade knives UK project.

Depending on the design of your knife, you may also need additional items such as drill bits, saws or file work.

The 7 parts of knives are the blade, bolster, tang, guard, handle, pommel and lanyard.

Blade:

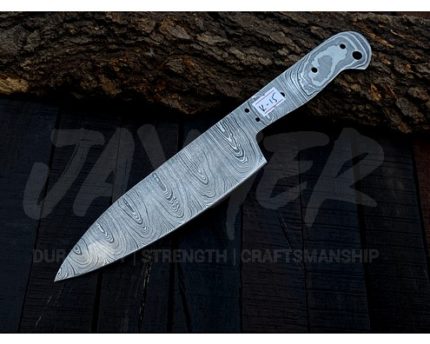

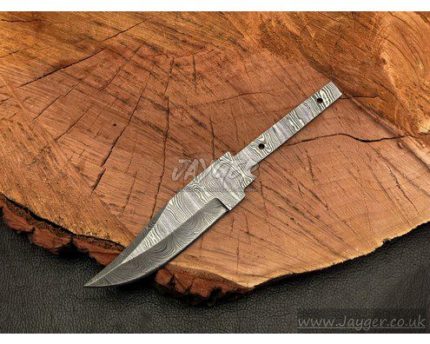

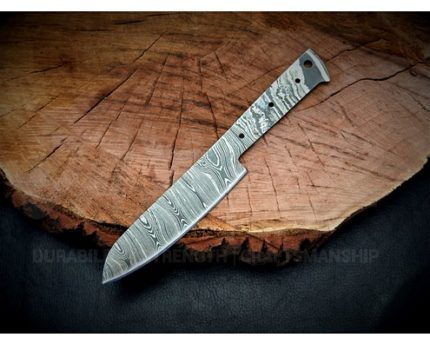

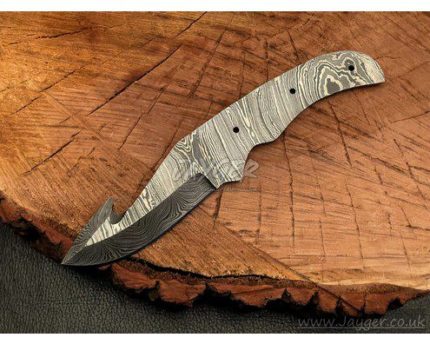

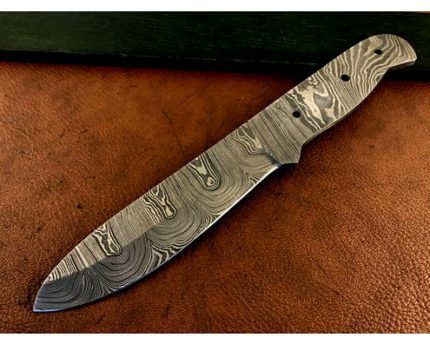

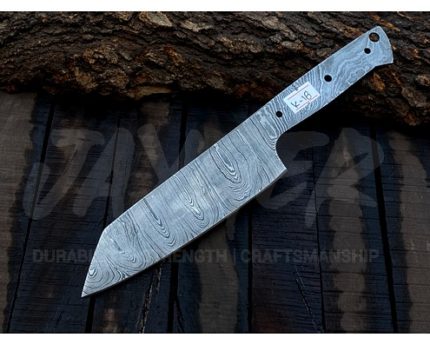

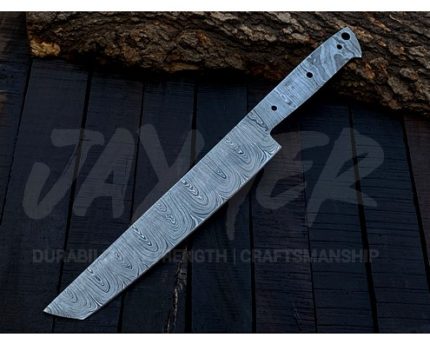

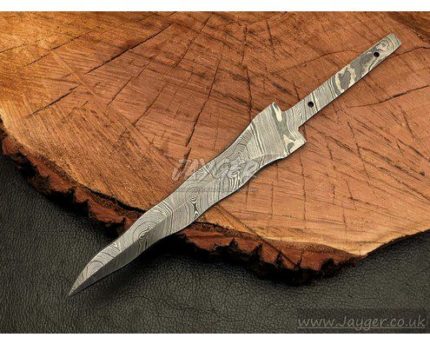

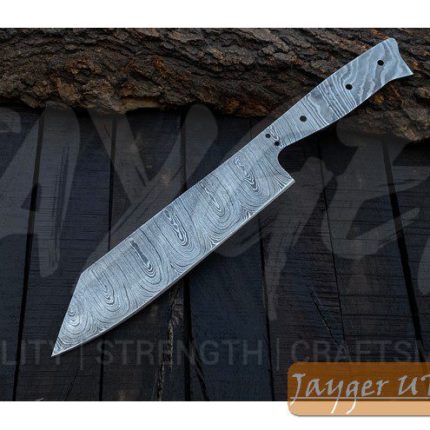

The blade is the knife’s cutting edge and can be made from carbon or Damascus steel blank

Bolster:

The bolster usually supports the sword and acts as a balance point between the blade and handle.

Tang:

The tang is an extension of the blade that runs into the handle.

Guards:

Guards protect users’ hands from slipping onto the sharp cutting edge, while handles provide

ergonomic comfort during use.

Pommels:

Pommels aid in securing a knife’s handle firmly to its tang, and lanyards offer additional security for your prized possession.

Mosaic Pins:

For decorative element & beautification mosaic pins are also used.

Does Forging a Knife Make it Stronger?

Forging a knife can add strength and character to your blade. It also gives you more control over the characteristics of the finished product, such as size, shape and hardness.

During forging, hammering on the steel shapes and compacts the metal, encouraging grain refinement and making it more homogenous across its surface for improved durability.

In addition, drawing out blade stock by lengthening it at high temperatures will make it stronger than if the same length was produced from flat bar chunks due to better grain alignment and fewer inclusions that can weaken the steel.

If a knife is of high-quality material and properly forged, it can last several lifetimes with proper care and sharpening.

Forging also adds unique texture, colors, and patinas that showcase the maker’s craftsmanship. Ultimately, knives forged using traditional methods are generally stronger than manufactured blades.

What is the Hardest Metal to Forge?

Damascus steel is the most rigid metal to forge, made from multiple layers of steel and iron. Because the folding of the metals can be so intricate and complex, only a select few can create it properly.

The combination of carbon steels such as 1095 and 15N20 alongside pure iron equalizes during forging, allowing you to achieve a unique design and finish in your blades.

This process results in a visually appealing product that is also unmatched in strength and durability.

Carbon Steel is the most common metal used in Knife Making Kit UK. However, other metals, such as titanium, can provide added durability and strength.

Titanium is lauded for its hardness, but it’s also more difficult to forge than steel. As a result of its robustness, grinding and polishing titanium are much more complicated tasks than other metals.

When forging a knife out of titanium, precise heating is essential since overheating may cause it to become brittle or melt.

High-quality knife makers combine traditional methods with modern technology when working with titanium for increased safety and accuracy.

What Material is Best for a Knife Handle?

The material you choose for your knife handle should be comfortable, provide a secure grip, and look great with the rest of the knife. Common materials used to craft knife handles include wood, antler, horn, micarta and G-10. Each material provides different benefits depending on the user’s preferences.

Wood is often preferred by traditionalists, while antler is a good choice for creating a more rustic look. For those looking for a durable option, G-10 and micarta are favored for their resistance to water and abrasions.

Who is the Most Famous Knife Maker in the UK?

Jayger is widely regarded as one of the UK’s most reputable knife makers. With decades of experience handcrafting knives, their work has been featured in global publications and exhibitions.

Their designs are favored by people worldwide for unparalleled beauty and precision craftsmanship. Whether you’re looking for a custom made knife, pocket tool or other custom-made accessories, Jayger’s portfolio of best handmade Knives UK is sure to provide what you need.

Why Choose Our Knife Making Steel Supplies UK?

There are plenty of places to buy knife making supplies UK-wide, but what makes Jayger stand out is the balance of quality and accessibility. We cater to beginners, hobbyists, and professional bladesmiths alike, with us you can rely on for consistency. Every knife making steel UK product is carefully chosen to help you design blades that are not just customised but also sharp, long-lasting and beautifully designed.

If you’re into knife making UK, then the first thing you’ll want is the right steel. Choose a good-quality blade to craft a durable and quality knife. Whether you prefer carbon steel for that sharp edge or something long-lasting like stainless, our collection has everything to shape, grind, and finish your knives. Check out our extensive collection and pick the right steel for knife making. We also have a knife making kit for beginners UK with all the essentials you’ll need to craft your knife. Let your next blade tell its story.